Specifications

- Effective protection against self-loosening of large bolted joints.

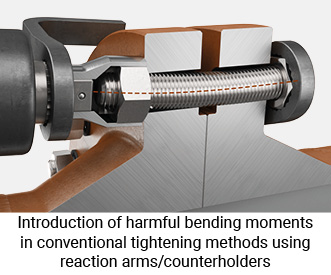

- No need for additional reaction arms or mounts.

- Prevention of accidents at work (e.g. pinching/crushing of the fingers, …).

- No damage to adjacent surfaces caused by the reaction arm.

- Use only with electrically, pneumatically or hydraulically operated torque tools.

- Prevents the screw/nut from turning when tightening.

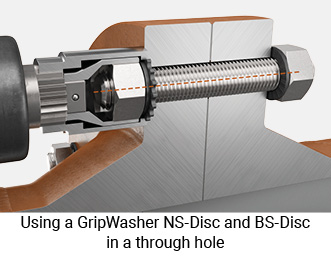

- The reaction torque of the torque tool is supported by a special dual socket that interlocks with the gear-shaped outer contour of the GripWasher NS-Disc.

- The tightening torque is applied axially – no harmful bending moments.

- Precise tightening due to low friction coefficient variation.

- Dual sockets adapted to easily fit powered tools from most well-known tool manufacturers.

- Immediate, effective locking even at low preload forces.

- Ideal for installation in confined spaces.

- Tightening and loosening possible with access from only one side.

- Friction based positive locking.Op wrijving gebaseerde positieve vergrendeling.

Technical data

- Anti-loosening device certified according to DIN 25201

- The gear-shaped contour of the lower washer in combination with a special dual socket ensures a reaction-arm free tightening

- Material: 1.1191 (C45E) with black zinc flake coating (flZnnc)

- Hardness: 485±25 HV0,3

- Corrosion resistance: min. 1,000 h in NSS-test according to ISO 9227

- Suitable for high-strength bolts and nuts up to strength class 12.9 / 12

- Bending moment and reaction arm free tightening method

- Available dimensions: M16 – M48 (5/8“- 1 ¾“)

- Other nominal sizes, materials and coatings available on request

More information about our

Watch the video: